Acrylic is a plastic material that can be used for many purposes. It provides a cost effective, durable material that can be fashioned into a variety of shapes and sizes, although acrylic sheets are the most popular form. This is because acrylic sheets can be turned into windows, retail displays, and even aquariums–all while providing better impact strength and a higher level of optical clarity than glass!

Interestingly, acrylic isn’t just a single form of plastic. It’s actually any type of plastic. It’s actually any type of plastic that contains derivatives of acrylic acid, but PMMA is by far the most common type of plastic. This is part of why multiple brands and varieties of acrylic plastic exist. Not only can acrylic plastic be chemically versatile, it can also be produced in two different ways: cast or extruded.

[wbcr_snippet id=”468″]When seeking to purchase acrylic plastic, it can be both interesting and beneficial to discover how both kinds of acrylic sheets are made. To ensure the correct plastic is chosen, and satisfy any curiosity about the production process in which our sheets are made, read on:

How Cast Acrylic Sheets Are Made

Cast acrylic has a high level of chemical resistance, and can be formed into a variety of shapes, sizes, and colors. In its sheet form, cast acrylic is a great choice if a durable material is needed. Not only that, but cast provides a greater range of thicknesses, making it ideal for large structures and installations.

Cast acrylic can be created using two different manufacturing techniques, batch cell and continuous production. Batch cell is the most commonly used process. This is a simple and easy way to create acrylic sheets ranging from .06 inches to 6 inches thick, and sheets ranging from three feet wide to several hundred feet! With this technique, sheets are often made-to-order. On the other hand, continuous production is a quick process that runs nonstop, requiring less labor. This manufacturing process is popular for exceptionally thin or narrow sheets.

No matter which technique is used, the first step when making cast acrylic involves mixing a monomer with a catalyst, which creates the polymer. As these two materials start to mix, the vat will actually look white. However, once thoroughly mixed, this molten mixture will become transparent. During this part of the mixing process, color can be added. These colors can be mixed and matched, allowing very specific shades— or even organic patterns like woods or granite—to be attained.

The next step is the casting process, the namesake of this production method. Before this step a disposable mold is created to fit the customer’s specifications. Then, the molten plastic is poured into this mold, and left to sit for a few hours until it becomes semi-solid and can be removed from the mold. Once the sheet leaves the mold, it’s transferred into an autoclave, which is specialty machinery that functions like a pressure cooker and an oven. The autoclave then uses heat and pressure to force air bubbles out of the plastic, giving it high clarity and an exceptionally solid composition. Refining the acrylic in the autoclave is not a short task, either—it typically takes over half a day!

Once the acrylic is removed from the autoclave, it’s time to finish the acrylic sheet. Edges are sanded down several times to ensure the sheet is smooth, using a smaller grain of sandpaper every time. While acrylic sheets can be sold at this point in the production process, it’s common for customers to choose to have the sheet buffed. The first step of the buffing process uses a cloth covered wheel to remove sanding marks, creating a smooth appearance for the acrylic sheet. If requested, the sheet can be polished again using another cloth covered wheel that is exceptionally soft. This creates a glossy appearance. At this point, the polished acrylic sheet is ready to be sold.

How Extruded Acrylic Sheets Are Made

Extruded acrylic has a different production process than cast acrylic, giving it different properties. Acrylic produced through this method is less expensive, and has a more consistent thickness. It’s popular for building retail displays because it can be machined and polished much more easily than cast acrylic.

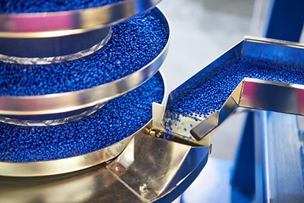

This process uses extrusion-grade polymer pellets as base. These pellets are created when a monomer is suspended in a water solution and a catalyst is added, creating droplets of polymers. These pellets are created when a monomer is suspended in a water solution and a catalyst is added, creating droplets of polymers. These pellets are then fed into a machine called an extruder, which heats pellets until they have a molten, liquid consistency.

From there, the molten plastic is put into a metal dye, which is similar to a mold. The dye then flattens on the molten plastic, creating a uniform sheet through pressure. Sheets can be made in a variety of thicknesses depending on how much space is between the dye, the sheets are then fed into cooling rows, which makes the acrylic sheet solid. From there, the sheet will be cut to the proper size, and finished using sanding and buffing techniques.

Conclusion

No matter which method is used to produce acrylic sheets, quality control is always the paramount concern. This isn’t just to prevent contamination, which can damage the integrity of the sheets—it’s done to prevent chemical reactions that can be unsafe to workers. This is primarily done by monitoring each step of the production process, including controlling temperatures from start to finish.

Acme Plastics is the expert in all things acrylic. We offer a range of acrylic sheets in a spectrum of colors, available in both cast and extruded. Visit our website if you’d like to see our full selection. If you have additional questions, contact us today.