It is common occurrence for people to confuse twinwall polycarbonate and multiwall polycarbonate. After all, twinwall and multiwall polycarbonate have the same properties while providing varying levels of insulation. Depending on the type of project you’re working on will dictate which of these two kinds of polycarbonate is the better fit. Below is a look at the differences between twinwall polycarbonate and multiwall polycarbonate and the insulation appropriate for various types of applications and projects.

Twinwall vs. Multiwall Polycarbonate

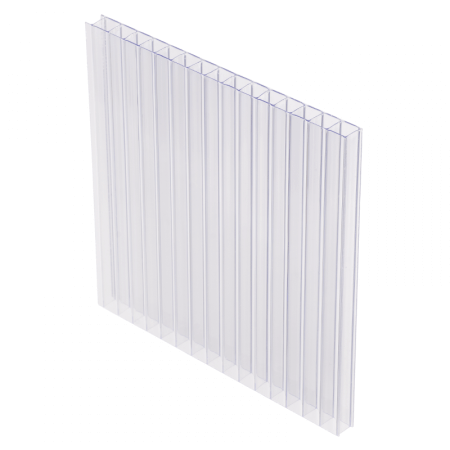

The major differentiator between twinwall polycarbonate and multiwall polycarbonate is the number of plastic sheet layers. Polycarbonate twinwall consists of two layers of plastic sheets, which are attached with a support layer. Twinwall is best used for structures such as greenhouses, carports, pergolas, cold frames, and sheds. It is a straightforward process to install this material. Alternately, multiwall polycarbonate consists of multiple layers of plastic sheets. Multiwall polycarbonate panels are a resilient and durable plastic often used in roofing, skylights, and diverse types of enclosures. Due to its multiple plastic layers, multiwall polycarbonate offers greater thermal insulation and sound resistance than its twinwall counterpart.

Twinwall Polycarbonate Use Cases

Greenhouses

The lightweight nature of twinwall polycarbonate makes it easy to work with when constructing greenhouses, making it a choice material as compared to its glass alternative. It is also an excellent material for greenhouses or any space related to horticulture as it is translucent, offers good thermal insulation, and high light transmission. Thereby, providing all the necessary components conducive to plant growth.

Cold Frames

Twinwall polycarbonate is a wonderful choice for cold frames (clear outdoor frame that allows sunlight in while protecting the plant from cold weather) as well as greenhouses. Twinwall polycarbonate is lightweight, durable, provides ideal thermal insulation, and optimal light transmission to keep plants within cold frames healthy and flourishing.

Sheds

Easy to maneuver and adhere, twinwall polycarbonate is a fantastic choice for shed windows and doors. Available in varying sizes, it is Impact resistant and durable, and an ideal choice for sheds as it can withstand harsh impacts from the elements when compared to its glass alternative.

Multiwall Polycarbonate Use Cases

Roofing

Due to its lightweight nature and ideal light transmission, multiwall polycarbonate sheets are the perfect material for roofing. Offering premium insulation properties for extreme weather conditions such as heavy rain, sleet, and snow, multiwall polycarbonate is durable, long lasting, and easy to install!

Cladding

Multiwall polycarbonate sheets offer a unique decorative look to any building’s exterior, but more importantly is an excellent choice for cladding as its superior insulating properties create unmatched thermal protection for any space. This dynamic choice is popularly displayed on a building’s exterior and can also be part of a structure’s interior.

Skylights

Based on its incredible light transmission and insulation properties, multiwall polycarbonate is a popular choice for skylights. Providing weather-safe security, multiwall polycarbonate sheets take the prize when compared to other comparable materials.

Enclosures

Multiwall polycarbonate is an ideal material for various kinds of enclosures ranging from swimming pools, pergolas, to outdoor patios. They are durable, weather-resistant and offer optimal protection against severe environmental conditions and have amazing insulative properties to maintain excellent climate control for indoor spaces, too.

Depending on the specifications of your projects you may pick twinwall polycarbonate over multiwall polycarbonate or vice versa. However, both polycarbonate products have a lengthy line of benefits including outstanding durability, light transmission, insulative properties, and transportability. If you are unsure about which material may be best for your next project, feel free to contact our team at Acme Plastics with any questions or for more information. We’ll gladly assist you.