Plexiglass, otherwise known as acrylic, is a versatile plastic that offers a variety of applicational uses. Given its rigid strength and superior visibility, plexiglass is a suitable material for a variety of commercial applications. But what about choosing the right material for everyday projects that don’t require commercial-sized materials?

As it turns out, there are several reasons plexiglass can be used around the house, or on your next small-scale project. With this in mind, here are some tips and tricks to help you get the most of out of your plexiglass without spending too much time or effort.

The Benefits of Plexiglass

Plexiglass is extremely shatter resistant and requires far more pressure to break or crack. Additionally, plexiglass maintains extreme transparency (up to 93 percent), making it an ideal glass alternative where strength and transparency are called for.

[wbcr_snippet id=”468″]

Another notable benefit of plexiglass is how easy the material can be sawed into a variety of different shapes and sizes. In other words, one larger sized plexiglass sheet can be used for a variety of small and medium sized projects. Lightweight and easy to handle, the material can be quickly cut to your project’s specifications.

Working with Plexiglass

While the material is easy to manage and cut, there a few tips to keep in mind:

- Avoid removing the thin plastic masking meant to protect the plexiglass surface until absolutely necessary

- When cutting plexiglass, always use metal-cutting saw blades and drills that are specifically made for acrylic sheets

- Avoid using saw blades with side-set teeth—ideally, saw teeth should be ground with zero degrees of rake and have uniform height and shape

- While cutting plexiglass to size, always use cooling (water or oil) when cutting pieces over 1/8″ thick or drilling plastic over 3/16″ thick

- Before you begin cleaning your plexiglass, always wet the material first

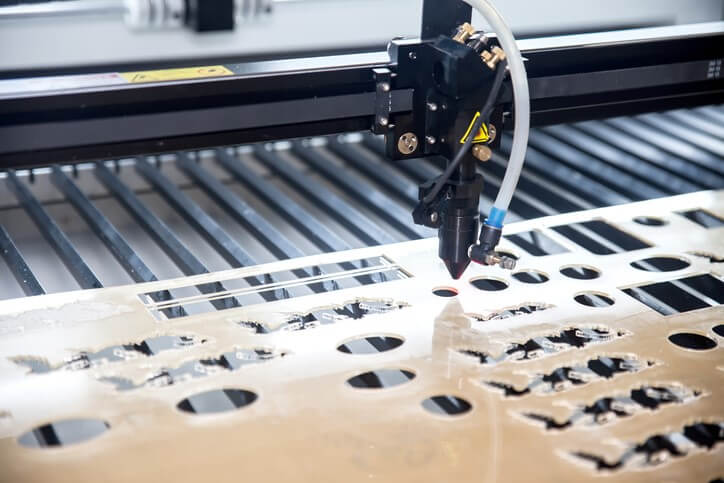

Cutting Plexiglass

When you are cutting plexiglass, you can use a wide variety of tools to get the job done, including laser cutting, a knife, scriber, power saw, table or circular saw, saber saw, hand saw, or router shaper will work. The key, however, is to ensure that the blade is specifically designed to cut acrylic, and that it is extremely sharp before you begin use.

Drilling Plexiglass

For the best results when drilling plexiglass, use drill bits that are specifically designed for cutting into acrylic. While regular twist drills can be used, they may need to be modified to keep the blade from grabbing and fracturing the acrylic. Additionally, you can modify a standard drill bit by grinding small flats onto both cutting edges. This way, the bits cuts with more of scraping action and avoids fracturing the plexiglass.

Bonding Acrylic

Ideally, you should always use solvent cementing for joining acrylic. You can solvent cement any two pieces through a capillary and dip or soak, which dissolves the contact surfaces to join the plexiglass.

If you do not want to do solvent cementing however, viscous cementing is another option you may want to consider. In this process, dissolved acrylic is used as actual cement.

In many cases, the edges of each piece of plexiglass should be smooth for the strongest possible joints.

Final Thoughts

Whether you’re working with plexiglass to create a new project or you’re using it to enhance an existing one, there are several ways to cut, shape, and mold this plastic to suit your needs. Contact us today to learn more.